limited edition: special titanium heatbreak made from Ti6-5-0.5

Due to its strength and lower thermal conductivity, titanium is much better suited to fulfill the functions of a thermal barrier than stainless steel. E3D-Online and other heatbreak manufacturers use the world's most widely used titanium alloy for their special titanium heatbreaks: Grade 5 (or also Ti-6Al-4V, EN 3.7165, UNS R56400). The Grade 5 titanium alloy has no major weaknesses, is regarded as an all-rounder and therefore accounts for more than 50% of the worldwide titanium volume.

I have had a heatbreak made according to E3D-V6 design which consists of the much rarer and unfortunately also more expensive titanium alloy 6-5-0.5. This has an even lower thermal conductivity than grade 5 titanium and is even stronger. So in the two main needed properties of a heatbreak better than titanium grade 5.

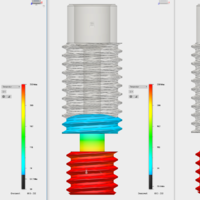

The heat flow in a heatbreak made of the titanium alloy 6-5-0.5 from hotend (250°C) to coldend (30°C) is therefore only about 1.78W. In relation to the stainless steel version (with about 6.37W) this is only 27.9% of the heat flow. This means that the coldend requires less than a third of cooling capacity and thus reliably prevents clogging. In addition, the transition zone, i. e. the point where the filament changes its state from solid to liquid, is clearly shortened. This results in better values for the retraction and the print.

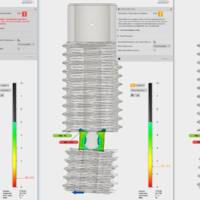

Furthermore, the higher yield strength of the titanium alloy makes the heatbreak more than 4 times more stable than the stainless steel version:

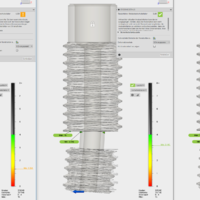

But that's not all. In order to go one step further than just choosing the best possible material, the borehole of the heatbreak was then extensively polished. In 4 additional working steps, the corresponding undersized bore hole was also ground and polished. As a result, the heatbreak has a mirror-smooth inner wall on which the melted filament can hardly adhere. Possible jams (known for printing with PLA and high retract values) are thus additionally counteracted. However, high retraction values are no longer necessary because the transition zone is significantly shorter.

For comparison:

AISI 303 (EN 1.4305, UNS S30300) Stainless Steel - main alloy components: Chrom, Eisen, Nickel

- density: 7,8g/cm³ (100%) - less is better

- thermal conductivity: 15 W/mK (100%) - less is better

- yield strength: 230 MPa (100%) - more is better

- raw material price: ~1,90€/kg (8mm Stab, 3m lang, Abnahme > 30kg) (100%) - less is better

- heat flow: 6,37W (100%)

Titanium Grade 5 (Ti-6Al-4V, EN 3.7165, UNS R56400) Titanium - main alloy components: Vanadium

- density: 4,4g/cm³ (56,4%) - less is better

- thermal conductivity: 6,8 W/mK (45,3%) - less is better

- yield strength: 910 GPa (395,6%) - more is better

- raw material price: ~30€/kg (8mm Stab, 3m lang, Abnahme > 30kg) (1578,9%) - less is better

- heat flow: 2,89W (45,4%) - less is better

Titanium 6-5-0.5 (EN 3.7155)- main alloy components: Zirconium, Molybdenum

- density: 4,5g/cm³ (57,7%) - less is better

- thermal conductivity: 4,2 W/mK (28%) - less is better

- yield strength: 990 MPa (430,4%) - more is better

- raw material price: ~70€/kg (8mm Stab, 3m lang, Abnahme > 30kg) (3684,2%) - less is better

- heat flow: 1,78W (27,9%) - less is better